-40%

1/4" Siphon Air Atomizing Fog Misting Jet Nozzle Sprayer Two-Fluid Gas-Water Mix

$ 3.16

- Description

- Size Guide

Description

1/4" Stainless Steel Adjustable Spray Atomization Humidifying Nozzles Two-fluid Gas-water Mixing Air Atomizing Nozzle SprinklerHigh quality viscous liquid adjustable air atomizing nozzle

Stainless steel air atomizing nozzle Adjustable spray atomizing humidifying nozzle Two-fluid gas-water mixing nozzle

1.Description

Material: Stainless steel

Inlet thread size: 1/4"

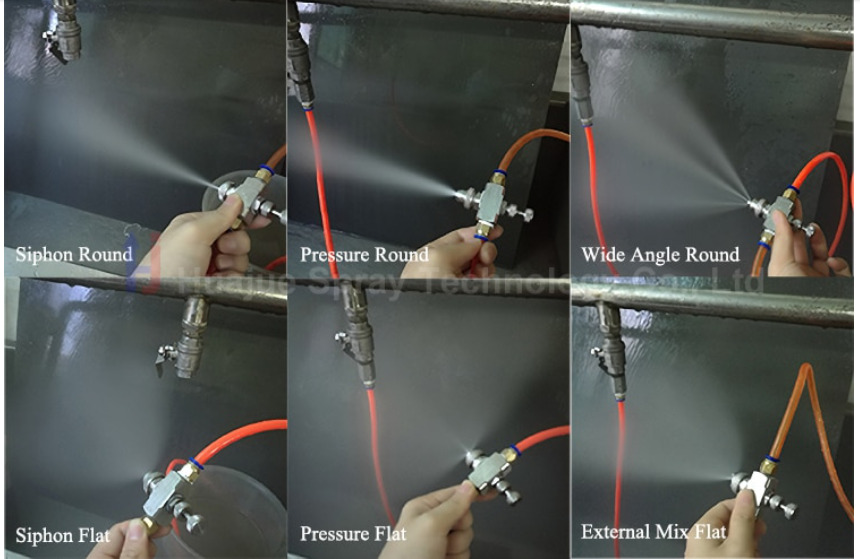

Spray pattern: Flat fan, Round

Configuration: Air cap, retainer ring, fluid cap, gaskets, nozzle body, needle vale

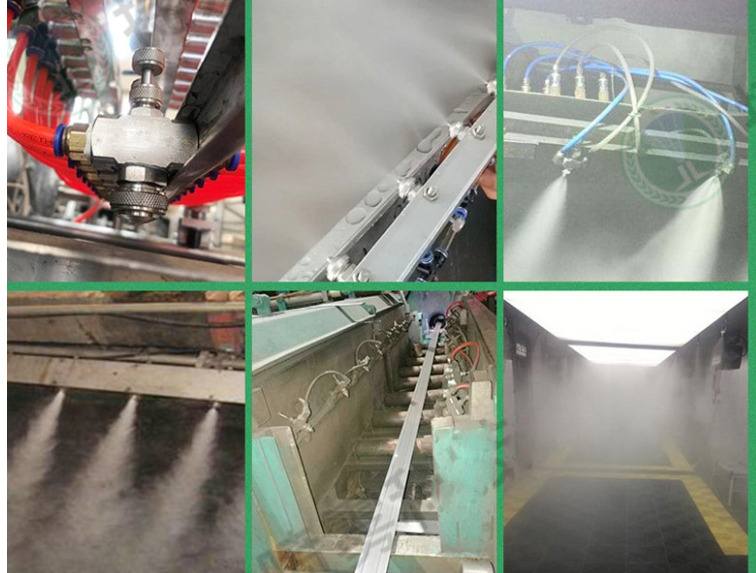

Applition: Dedusting, fire fighting, cooling system, humidifying, lubricating

2.Details:

Each series is abaliable with a pressure spray set-up or siphon spray set-up

each set-up provides a specific spray pattern with a specific capacity ans spray coverage range performance.

spray set-ups are interchangeable for each nozzle series

round spray:extended full cone round spray pattern

wide angle round spray :hollow cone-type,wide angle round spray pattern

360circular spray :hollow cone-type 360 circular spray pattern

flat spray:extended flat or sheet-type spray pattern

deflected flat spray :extended flat or sheet-type spray diverted awat from the axis of the inlet connection

each spray set-up consists of an air cap and fluid cap

3.Atomization control features

achieved by adjusting the air and liquid pressure in the spray set-up

obtaining finer atomization is air pressure and or lowering the liquid pressure ,resulting in a high ratio of air flow rate to liquid flow rate.

4.Internal Mix Features

liquid and air are mixed internally to produce a completely atomized spray .

liquid and gas streams are not independent and a change in air flow will affect the liquid flow

internal miz uses pressure set -ups and is abailable with the following spray patterns :

360 circular spray deflected flat spray , elliptical spray , flat spray , round spray, wide angle round spray

5.External mix features

liquid and air streams are mixed outside of the nozzle

air and liquid flow can be controlled independently

effective for higher viscosity liquids and abrasive suspensions

external mix can use siphon set-ups or pressure set-ups

when a siphon set-up is used a round spray pattern is produced

when a pressure set0up is used, a flat spray pattern is produced

6.Design Features:

1. Inner structural design makes liquid and air mix, and then sprays fine. Normally, we could increase the air pressure or reduce the liquid pressure, so that we could make the nozzles spraymore fine droplets (about 30micron).

2. Keeping liquid pressure and air pressure unchanged, as Adjustable air atomizing nozzle could adjust liquid flow rate, and then it also could spray according to your requirement.

3. Every spraying device consists of air cap and liquid cap. Spray pattern has flat fan, round, and wide- angle round spray. Nozzles also has widely flow rate. Inlet thread has different size which could be suitable for many pipe systems.

4. Air atomizing nozzle structure has pressure type, siphon type and gravity type.

Note: when you use air atomizing nozzle, air pressure is necessary, but liquid pressure is not demanded. You could use pressure atomizing type with liquid pressure, while could use siphon atomizing type or gravity atomizing type.

5. Air atomizing device has two mixed type: inner mixed type and external mixed type. Inner mixed type could spray very fine, and it is suitable to use under many conditions. While, it is a good choose to use external mixed type to spray viscosity liquid.

7.Application:

1. Moistening and derusting

2. Air moistening

3. Chemical treatment

4. Spray chemical

5. Spray liquid

6. Humidify tobacco leaf

7. Tablets coating

8. Cool gas

9. Sterilization

10. Cool compenert

11. Spray candle on fruit

12. Ceramic Tile - Glazed

13. Spray lubricant

Atomization structure

1. Pressure type

1) Internal mix

when using a pressure-fed liquid system, the liquid is supplied to the nozzle under pressure, the liquid and compressed air or gas are mixed internally to produce a completely atomized spray.

2)External mix

By changing the gas pressure without altering the flow rate to control the liquid atomization. This hybrid approach to high viscosity liquid and grinding agent suspension is more effective.

2. Siphon type

when using syphon or gravity-fed liquid system, it can be supplied to the fluid by siphoon or gravity-fed. In these devices, the liquid is absorbed and sent to the gas stream through conveyer where it is atomized in the gas stream.